|

General Magnetic Co., Ltd.

|

Sintered Neodymium Iron Boron

| Price: | 0.01~100.0 USD |

| Payment Terms: | T/T,L/C,WU;paypal |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

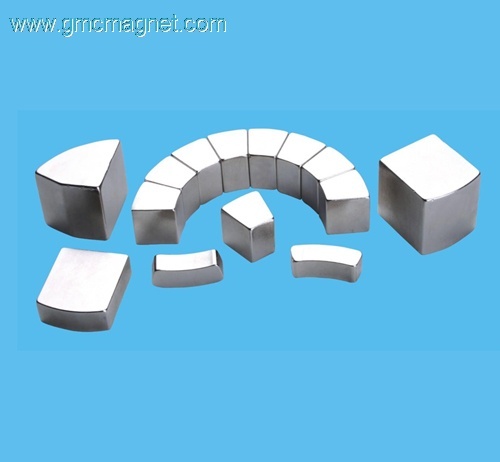

sintered Neodymium Magnets tile

1.Material:Neodymium-Iron-Boron

2.Size:Various or Customized

3.Coating:Ni,NiCuNi,ZN

4.Lead time:7-25 days

sintered Neodymium Magnets tile

Description

1. Material: Sintered Neodymium-Iron-Boron

2. Grade: N35 to N52; N35M to N50M; N35H to N48H, N35SH to N45SH; N30UH to N40UH, N30EH to N38EH.

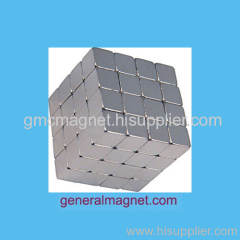

3.Shape:Block,Disc,Ring,Segment,Arc,Cylinder,Round,Tile,Disk,Block,etc.

4.Size: various or according to clients' request.

5.Coating:Zn,Ni,NiCuNi,Sliver,Epoxy,etc.

6.The main Applications of magnets

1)Acoustics: speakers, microphone;

2)Transportation: automobile, Motor Assemblies;

3)Electronics: Sensors, Instrumentation, Transducer;

4)Electrical Engineering: Generator, Windmill;

5)Medical Equipments: MRI (Magnetic Resonance Imaging), Magnet Therapeutic Apparatus;

6)IT industry: Loudspeakers, Earphones, printer, etc;

7)Communication equipments: Mobile Phone;

8)Home appliance: VCD, DVD, Laser;

9)Promotion Items: Holder/clip/clap;

10)Aeronautics and Astronautics: Radar;

11)Hi-Tech Research: Electron Accelerator, PMQ

12)Light Industry: Gift/Toy

Parameters:

Grade, Size or Drawing, Coating, Quantity, etc;

Packaging & Shipping

Standard Export Carton or Cartons, HDPE high quality plastic box,Cartons with pallet,etc.

All available shipping ways could be applied, by courier(TNT,UPS,etc.), by air or by sea.

Buyer Guide

In order to quote you the best price quickly, please provide the following information:

1.Product size,grade,coating,etc.

2.Order quantity;

3.Attached the drawings if customized

4.Any special packing or other requirements

Our Services

1. Fast reply: all your enquiry will be replied within 24 hours;

2. Reasonable price: we are direct manufacturer and able to offer better price;

3. Good quality: we are experienced in quality control;

4. Fast delivery time:7-25 days

Residual Induction (Br):

Also called "Residual Flux Density". It is the magnetic induction remaining in a saturated magnetic material after the magnetizing field has been removed.This is the point at which the hysteresis loop crosses the B axis at zero magnetizing force, and represents the maximum flux output from the given magnet material. By definition, this point occurs at zero air gap, and therefore cannot be seen in practical use of magnet materials.

Coercive Force (Hc):

The demagnetizing force, measured in Oersteds, necessary to reduce observed induction, B, to zero after the magnet has previously been brought to saturation.This value indicates the ability of magnet to keep its magnetic force unchanged.

Maximum Energy Product (BHmax):

The magnetic field strength at the point of maximum energy product of a magnetic material. The field strength of fully saturated magnetic material measured in Mega Gauss Oersteds, MGOe.

How to Choose Permanent Magnet Materials

Each permanent magnet material discussed above has its own pros and cons. How to choose the right one for your particular application is a challenge to any user. A balance between cost and performance must be considered in selecting of permanent magnet material. Following is a Comparison Table to help you select a right permanent magnet material for your applications.

Permanent Magnet Material Comparison Table

Note: The data listed in the table are for reference only

Material | Maximum Energy Products | Coercivity | Maximum Working |

Nd-Fe-B (sintered) | Up to 49 | Up to 30 | 200 |

Nd-Fe-B (bonded) | Up to 10 | Up to 11 | 150 |

Sm-Co (sintered) | Up to 30 | Up to 25 | 350 |

Sm-Co (bonded) | Up to 12 | Up to 10 | 150 |

Up to 9 | Up to 2 | 550 | |

Up to 4 | Up to 3 | 300 |

Neo IB magnet is mainly made of Neodymium, Iron and Boron, with excellent magnetic property, abundant raw material in China and reasonable prices, Neo IB can be used as an ideal magnet in mini-motor, permanent magnet instrument, electronic industry, auto industry, petro-chemical industry, nuclear magnetic resonance, sound device, magnetic suspension system, magnetic transmission machine and iatrical apparatus and etc.

Neo IB magnet surface is usually treated with some special methods to avoid corrosion, including zinc, nickel, tin, silver, gold plating, phosphate and spraying epoxy resin etc.

Please send us your drawings or specifications, we will reply to you within 24 hours!